LaserBlast-200-Rental

Price per week under a 3 years contract

Free Shipping in Canada and U.S.

Buy now, get in 10 days

Allied Scientific Pro (ASP) has developed and manufactured a laser cleaning system to replace traditional blast media methods, sand, glass beads or dryice . Offering full control over a wide range of parameters allows for precise cleaning with the ability to retain patinas or industrial parts intact.

With a long legacy of expertise in laser nano and micro machining process, ASP is capable of offering a state of the art laser system to address the needs of the industrial applications. Our laser system is compact, robust and has a long lifetime with low or no maintenance for years. We are using the latest laser and scanner technology to offer high quality performance and speed efficient cleaning without causing damage to the object.

ASP laser laboratory services can assist and by establishing optimal parameters for your application.

Available power 100, 200, 500, 1000 Watt output laser from the laser head

5 meters or more optical fiber delivery for remote access

- Short pulse with no thermal effect

- Long lifetime with the latest laser technology made in the USA

- Low cost of operation

- Water cooled which helps preserve the building

- One worker operation

- Laser safety glasses included

- 1 year warranty

Application

Black steel A106 Grade B for pipeline ( see video section)

Welding preparation of surfaces

- Rust and oxidation cleaning

Surface smoothing varnish

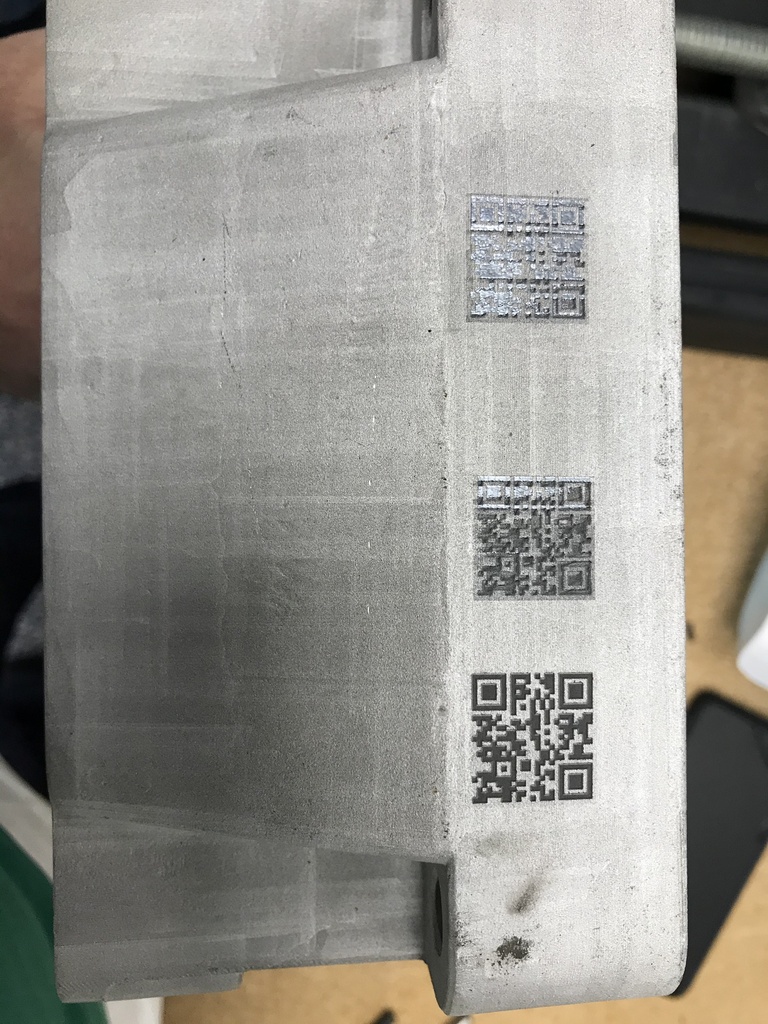

Surface texturing for paint adhesion

Turbo engineer combustion chamber cleaning for power plant

Radioactive surface cleaning for nuclear plant

Part grease cleaning

Coating removal

Corrosion treatment

Key advantages:

Reduce total effective cost per sq/ft by 40% to 60% depending on the material

Reduce labor cost: only 1 operator

Avoid to damage the material base substrate

No need for water, avoid water infiltration

No need for chemical

Reduce 90% of toxic waste disposal cost : solvent, media blasting, liquid waste

Reduce risk of injury at work

Environmental friendly

Reduction in injury rate

Reduce cost of protective clothing

Increase lifetime of the substrate your are trying to conserve

Zero consumables

Zero preparation cost

Easy on scheduling

Note: Effective cost includes; labor, preparation time, damage prevention, power consumed, amortized equipment cost, consumable material costs and residue disposition costs.

Key advantages of Laser cleaning of LaserBlast-200

Laser cleaning best in class!

| Laser Engine | 100 Watts, 200 Watts, 500 and 1000 Watts also available |

| Pulse duration | 10 to 30nsec (may vary) |

| Cooling | Water cooled for 200Watt |

| Estimate Lifetime Expectancy | 10 years |

| Repetition rate | 1 to 55 KHz ( may vary) |

| Peak Power | Kilowatt |

| Design | No moving parts in the laser engine |

| Voltage and power consumption | 3x400-480VAC ±10% 50/60Hz/4200Watts |

| Scanner Head; | |

| Flexible configuration | Software allows for many types of scans; Round, Line, square, can be adapted to all types of surfaces or shape |

| Robust | Made of a Aluminium, 2 handle bars and protective lens cap |

| Working distance | 12 to 18 inches |

| Laser enclosure | |

| IP level | IP55 |

| Cooling | 4 Cooling fans fully protected from water |

| Handle bar | Robust handle bars on each side for manutation |

| Extension electrical cord | 30 feets 120V |

| Computer | Robust computer or tablet with full control and easy to use |

| Software | Ezclean software included |

| Laser presets | 3 presets cleaning process included for Radiation contamination |